Across the world, manufacturers are rethinking how factories are designed, built, and operated. As environmental responsibility becomes a defining business value, green factory design is emerging as a powerful solution that aligns economic performance with sustainability. These new-generation facilities combine technology, architecture, and energy management to reduce waste, conserve resources, and inspire a more sustainable global industry.

Introduction — The Rise of Sustainable Industry

Industrial production has long been seen as a major contributor to global emissions and resource depletion. But in recent years, a new wave of innovation has transformed the manufacturing landscape. The demand for clean energy, ethical production, and resource efficiency has pushed industries to adopt environmentally responsible models. This shift isn’t just a reaction to climate change—it’s a fundamental redesign of how factories function.

The essence of green factory design lies in combining sustainability and productivity. Facilities are now engineered to optimize performance through energy-saving systems, intelligent layouts, and the use of recyclable materials. As more nations invest in low-carbon industrial parks and eco industrial zones, the green factory movement is setting a global precedent for responsible growth.

What Defines a Green Factory?

The Core Principles of Sustainable Industrial Architecture

A green factory is not merely a building with solar panels or green paint—it’s a system designed to operate efficiently from start to finish. The foundations of green factory design include resource efficiency, renewable energy integration, waste minimization, and optimized workflows. These principles are supported by smart manufacturing technologies that enable real-time monitoring and continuous improvement.

True sustainable factories focus on four major aspects:

- Energy efficiency: implementing LED lighting, passive cooling, and solar generation.

- Water conservation: using rainwater harvesting and greywater recycling systems.

- Material optimization: designing modular structures with recyclable components.

- Waste reduction: tracking and reusing production scraps in new processes.

These combined measures create a closed-loop system where every stage of production supports environmental goals while maintaining high output quality.

Building Design that Reduces Environmental Impact

Architectural design plays a crucial role in minimizing the environmental footprint of manufacturing facilities. Modern factories use passive ventilation systems, skylights, and reflective roofing to reduce energy demand. They also prioritize flexible floor layouts that can adapt to changing production needs without major renovations.

One of the most significant advances has been the rise of prefabricated steel warehouse systems. These modular constructions allow for faster assembly, lower material waste, and easier recycling. Steel structures also offer exceptional durability, extending the building’s lifespan while minimizing maintenance requirements. This approach demonstrates how sustainable design can coexist with industrial-scale performance, setting new standards for efficiency in manufacturing architecture.

The Role of Smart Manufacturing in Green Factory Design

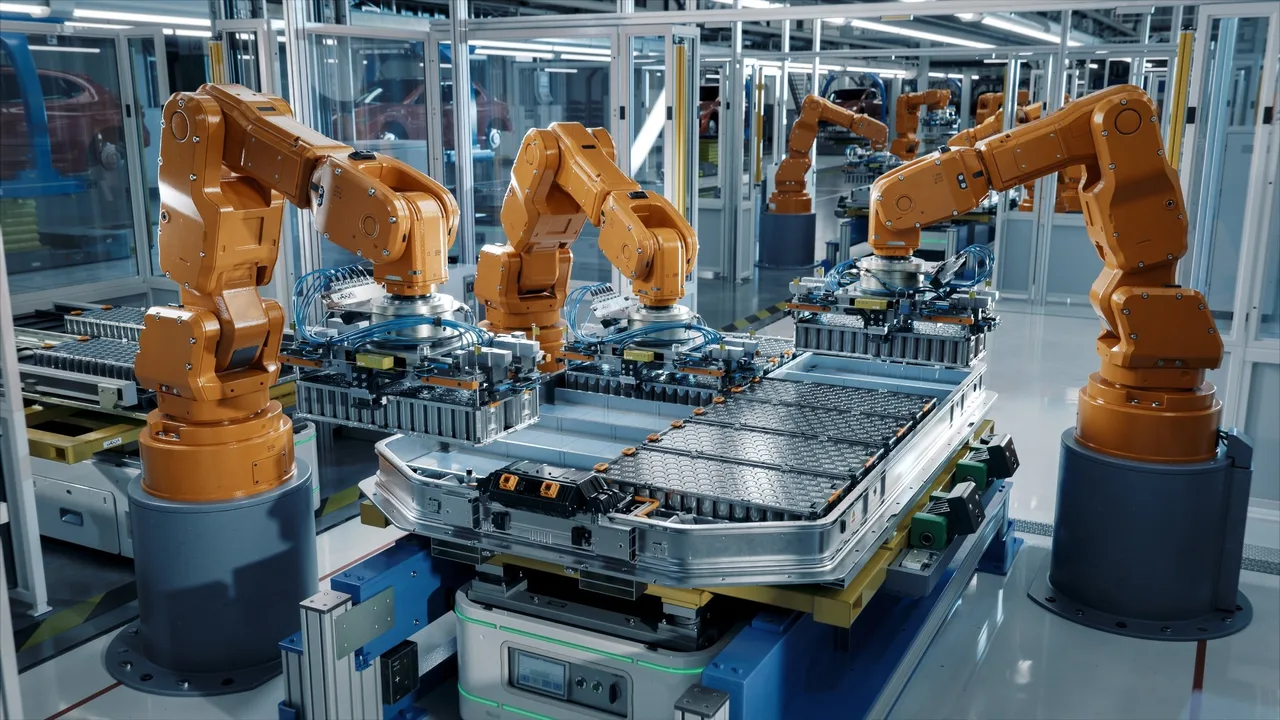

Automation and Data-Driven Efficiency

The integration of smart manufacturing has revolutionized how green factories operate. Advanced robotics and AI-driven production lines help minimize waste by optimizing resource use and predicting maintenance needs. Through continuous data collection, factories can identify inefficiencies in real time and adjust operations automatically to reduce energy consumption.

For instance, predictive analytics can anticipate equipment wear before breakdowns occur, preventing costly downtime and material loss. Automated material handling systems ensure that every raw material is tracked, stored, and used with minimal waste. This not only improves efficiency but also strengthens transparency in sustainability reporting—an increasingly important factor for ESG compliance.

Real-Time Monitoring and Lifecycle Management

In the past, industrial sustainability relied heavily on static assessments conducted at project completion. Today, sensors and IoT platforms allow facilities to monitor environmental performance continuously. Metrics like air quality, temperature, and energy usage are captured in real time, providing valuable insights for ongoing improvement.

By applying digital twins—virtual replicas of physical systems—companies can simulate future performance scenarios, plan upgrades, and track lifecycle impacts. This capability transforms traditional operations into dynamic ecosystems that evolve toward higher efficiency every year. In essence, smart manufacturing doesn’t just automate production; it teaches factories to think and adapt like living systems.

Eco Industrial Zones — A Blueprint for the Future

Collaboration Between Factories, Communities, and the Environment

The concept of eco industrial zones takes sustainability to a larger scale. Instead of treating each factory as an isolated unit, these zones connect multiple industries to share resources and reduce collective waste. For example, one factory’s byproduct may serve as another’s raw material, while shared energy systems minimize redundancy and cost.

Eco zones also promote social responsibility by integrating green spaces, public transport access, and community engagement programs. This holistic approach reflects a shift from competitive to collaborative industry models, where collective innovation drives sustainable growth. Countries like Denmark, China, and Singapore have already developed industrial symbiosis parks that exemplify this system-level efficiency.

Policy and Infrastructure Support

Government policies play a vital role in expanding green factory design initiatives. Tax incentives, carbon credits, and investment grants encourage manufacturers to transition toward low-emission models. Additionally, environmental certification programs and urban planning regulations ensure that industrial areas meet stringent sustainability benchmarks.

As ESG principles and global net-zero targets become mainstream, collaboration between policymakers, private sectors, and local communities will define the next generation of eco industrial development. The success of these programs depends on shared responsibility and transparent accountability—a model that’s rapidly gaining traction in industrial economies worldwide.

Case Studies — Factories Leading the Green Revolution

Prefabrication and Sustainable Construction

Across Asia, Europe, and North America, manufacturers are proving that industrial performance and environmental responsibility can coexist. One of the most notable approaches is the adoption of prefabricated and modular construction systems for large-scale facilities. These methods drastically reduce on-site waste and construction time while ensuring high precision and energy efficiency.

Companies specializing in steel structure engineering are among the pioneers of this movement. The prefabricated steel warehouse model has become a benchmark for modern industrial design. By using recyclable steel materials and efficient fabrication techniques, these factories cut emissions and minimize their environmental impact. Beyond performance, this type of design offers flexibility—factories can expand or adapt their layouts to new technologies without complete rebuilds, further extending their life cycle.

Global Examples of Innovation

Japan’s eco-industrial clusters showcase how advanced automation can coexist with traditional craftsmanship. Factories powered by renewable energy sources, paired with heat recovery systems, have achieved near-zero waste operations. In Germany, automotive plants utilize closed-loop water systems and integrate urban farming within their campuses to offset carbon emissions. Meanwhile, Scandinavian manufacturers are redefining green factory design with timber-based hybrid structures and geothermal heating, setting an example for the world.

What unites these projects is not their scale but their commitment to measurable progress. Real sustainability is achieved when efficiency metrics—energy, water, and emissions—are verified and published. Transparency is the common denominator in every success story of industrial innovation.

The Economic and Social Impact of Green Factories

Cost Efficiency and Brand Value

For many companies, the shift to sustainability begins with cost savings. Energy-efficient lighting, smart HVAC systems, and optimized workflows drastically reduce operating expenses. Over time, lower energy and maintenance costs offset the initial investment in green infrastructure.

But the economic benefits extend beyond the balance sheet. Consumers and investors increasingly reward companies that demonstrate authentic environmental responsibility. A factory designed with sustainable principles enhances brand credibility and positions the organization as a leader in responsible innovation. In the age of ESG-driven investment, green factory design is no longer optional—it’s a competitive advantage.

Improving Workforce Well-Being

The benefits of green factories aren’t limited to environmental performance—they also improve human health and productivity. Better air quality, natural lighting, and ergonomic layouts create healthier workspaces, which in turn reduce absenteeism and enhance employee morale. A well-designed factory provides psychological benefits that translate into stronger retention rates and higher efficiency.

Workers are no longer viewed as cogs in a machine but as key stakeholders in a sustainable ecosystem. This human-centered design philosophy transforms industrial spaces into environments where people, technology, and nature coexist harmoniously.

Challenges in Green Factory Design

The Cost Barrier and Misconceptions

Despite growing awareness, many businesses still view sustainability as an expense rather than an investment. Upfront costs for renewable systems, automation, and certification can deter decision-makers, especially in developing economies. However, the misconception that “green” equals “expensive” overlooks the long-term financial and reputational returns of sustainable infrastructure.

When evaluated through total lifecycle cost analysis, sustainable factories consistently outperform traditional ones. The payback period is often shorter than expected, especially when factoring in energy savings, government incentives, and reduced waste management costs. As financing options expand, the transition to sustainable production is becoming more accessible than ever.

Integrating Legacy Infrastructure

Another challenge lies in retrofitting older industrial facilities. Many existing plants were not designed with sustainability in mind and may require significant upgrades to meet modern standards. However, rather than rebuilding from scratch, companies can adopt phased transformation models—starting with energy audits, LED retrofits, and digital monitoring systems.

Through incremental change, even legacy factories can align with modern green factory design standards. The key lies in setting achievable targets and investing in technologies that deliver measurable improvements without disrupting core operations.

The Future of Industrial Sustainability

Digital Transformation Meets Environmental Responsibility

The future of sustainable manufacturing lies in data-driven decision-making. Digital twins, AI-assisted design, and blockchain-based transparency tools will soon become standard components of industrial ecosystems. These technologies will enable manufacturers to trace every material, monitor every process, and report every emission with accuracy and accountability.

In the coming decade, we can expect tighter integration between smart manufacturing and sustainability frameworks. Factories will function as intelligent networks that self-optimize for performance and efficiency. Combined with renewable energy systems and circular supply chains, this transformation will redefine how industries grow and interact with the environment.

Towards a Circular Industrial Economy

The next evolution of eco industrial zones will emphasize circularity—where every output becomes an input for another process. Waste heat from one plant could power neighboring facilities, while industrial byproducts are repurposed as raw materials. Collaboration and data sharing will be the backbone of this new model, reducing global waste and resource consumption dramatically.

Ultimately, this vision reimagines manufacturing not as a burden on the planet but as a regenerative system. It’s a collective effort that connects technology, governance, and ethics into one sustainable framework for global progress.

Conclusion — Building Factories for a Better Planet

Green factory design represents the convergence of innovation, efficiency, and environmental integrity. It’s more than an architectural trend—it’s a transformative movement redefining how we build, produce, and consume. From intelligent automation to sustainable materials, every aspect of the modern factory contributes to a shared mission: achieving growth without harming the planet.

By embracing prefabrication, data-driven efficiency, and collaborative planning, industries can lead a new era of responsible manufacturing. The green factory revolution is not a distant dream—it’s already underway, inspiring global change one structure at a time.