In today’s fast-changing industrial landscape, companies are realizing that speed alone no longer defines competitiveness — automation energy efficiency does. As global energy prices fluctuate and governments tighten carbon emission policies, manufacturers are under increasing pressure to produce more with less. Automation offers a way out of this dilemma, transforming factories into intelligent ecosystems that optimize every watt of energy used. By merging advanced robotics, sensors, and data analytics, industries are achieving what once seemed impossible: high productivity with minimal environmental impact.

Introduction — Why Energy Efficiency Defines the Future of Industry

Industrial energy use accounts for roughly one-third of global consumption. As economies scale and production demands grow, energy costs can quickly erode profit margins. This is where automation steps in — not just as a productivity enhancer, but as a catalyst for energy transformation. The idea behind automation energy efficiency is simple yet revolutionary: smarter systems waste less energy. By analyzing real-time data and making autonomous adjustments, machines can work only when needed, at optimal speed, and under ideal conditions.

Automation aligns perfectly with the principles of green manufacturing, helping industries achieve sustainability targets without sacrificing growth. From lightweight robotics to AI-driven control systems, smart factories are setting a new standard for energy-intelligent production across all sectors.

Understanding Automation and Its Role in Energy Efficiency

From Manual Labor to Smart Industry

The manufacturing sector has evolved dramatically from human-operated machinery to interconnected, self-regulating production systems. Early industrial revolutions focused on mechanical output; the fourth one is centered on intelligence and efficiency. The concept of smart industry integrates information technology, IoT (Internet of Things), and data-driven analytics to create a synchronized network of equipment that communicates continuously.

In this system, every motor, conveyor, or robotic arm is linked to an energy management network. When demand drops, the system reduces power automatically. When a specific process needs more resources, it redistributes energy intelligently without human intervention. This dynamic balance leads to significant reductions in both operational costs and emissions.

Key Principles Behind Energy-Saving Automation

At its core, automation energy efficiency relies on feedback loops and predictive modeling. Smart sensors collect data on temperature, vibration, and load intensity, while AI algorithms interpret it in real time. If a machine starts consuming more energy than expected, the system identifies the anomaly and takes corrective action—either by recalibrating performance or scheduling maintenance.

Modern automation systems operate on three fundamental energy principles:

- Real-time monitoring — Sensors track every stage of production, from raw material processing to packaging, ensuring no excess energy is wasted.

- Predictive control — AI forecasts when machines should run at full capacity or idle, aligning energy consumption with production demand.

- Self-optimization — Automation networks learn from data, improving efficiency over time without manual adjustment.

This approach transforms manufacturing into a proactive process—anticipating needs rather than reacting to inefficiencies.

How Automation Improves Energy Efficiency

Real-Time Energy Monitoring and Control

One of the clearest advantages of automation is its ability to track energy consumption precisely. Smart meters and IoT-enabled devices continuously measure how much power each piece of equipment uses. If energy spikes occur, systems automatically adjust lighting, ventilation, or mechanical speed to balance output. For example, variable frequency drives (VFDs) in motors can lower power use by adjusting motor speed instead of running continuously at full throttle.

In large-scale facilities, integrated automation networks allow central control rooms to visualize performance across entire plants. This not only reduces waste but also provides historical data to guide future energy strategies. The result is a self-regulating energy ecosystem—where efficiency is built into every operation.

Predictive Maintenance and Equipment Longevity

Traditional maintenance schedules often result in unnecessary repairs or energy losses from poorly tuned machines. Predictive maintenance, powered by AI and automation, solves this by analyzing data patterns to predict when a component will fail or underperform. Machines that operate outside of their efficiency range are flagged immediately, reducing both downtime and wasted power.

For example, in an automated milling plant, AI systems detect bearing friction before it escalates into a mechanical issue. Maintenance crews receive alerts early, allowing minor corrections instead of full shutdowns. This approach extends equipment life, cuts electricity use, and supports continuous productivity—all pillars of smart industry design.

Case Studies in Green Manufacturing

Energy Savings in Automotive and Electronics Industries

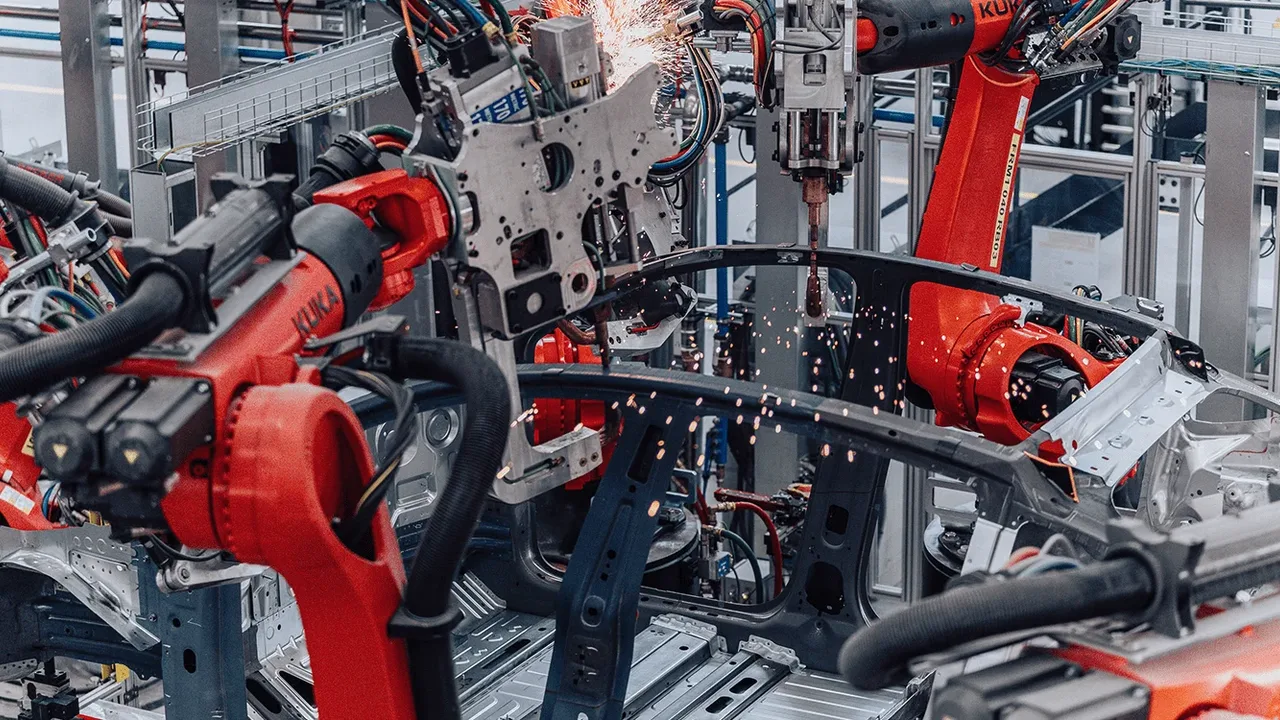

Manufacturers across multiple sectors have adopted automation not only for precision but for measurable energy reduction. In the automotive industry, robotic welding lines now coordinate through energy management systems that shut down inactive stations within milliseconds of inactivity. Some factories have reported 25–30% energy savings after integrating intelligent automation.

Similarly, electronics manufacturers have automated climate control and material handling. By combining data from hundreds of sensors, they optimize air conditioning and lighting in real time, leading to energy savings that compound across thousands of production cycles.

Integration with Renewable Energy Sources

Automation also bridges the gap between industrial energy use and renewable generation. Factories equipped with solar arrays or wind turbines often face inconsistent energy supply due to weather fluctuations. Smart automation systems synchronize production schedules with power availability—reducing grid dependency during peak sunlight or wind hours. This harmony between automation and renewables is a key driver of green manufacturing transformation worldwide.

Modern energy management platforms, as documented by research shared through the International Energy Agency, demonstrate how automated demand response systems dynamically match energy supply with factory operations, creating more resilient and efficient production environments.

Benefits Beyond Energy Savings

Improved Productivity and Cost Efficiency

Energy-efficient automation does more than just lower electricity bills — it enhances overall productivity. When equipment operates at optimal performance, output becomes consistent, quality improves, and the need for rework decreases. Every kilowatt saved contributes to higher yield per unit of energy, which in turn translates to greater profitability.

In highly competitive industries, even a small percentage increase in efficiency can have a major financial impact. For example, smart production systems that synchronize conveyor speeds, lighting, and HVAC systems based on workload can save millions annually. These efficiencies also make it easier for companies to reinvest in innovation, modern machinery, and employee upskilling.

Environmental and Social Impacts

The environmental benefits of automation energy efficiency ripple across entire value chains. Reduced power consumption means fewer carbon emissions, aligning manufacturing with the principles of green manufacturing and global sustainability frameworks like the UN’s Sustainable Development Goals. This cleaner approach not only benefits the planet but also enhances corporate reputation and compliance with ESG (Environmental, Social, and Governance) standards.

Automation also supports safer, healthier workplaces. Smart systems monitor air quality, heat exposure, and machine performance, alerting operators before conditions become unsafe. When technology safeguards both people and the planet, the concept of “smart industry” gains its full meaning.

The Technology Behind Automation Energy Efficiency

Role of Industrial IoT and Smart Grids

The Industrial Internet of Things (IIoT) serves as the nervous system of modern factories. Sensors installed across equipment collect granular data on energy use, production rates, and environmental conditions. When connected to smart grids, factories can interact directly with utility providers—shifting energy consumption away from peak hours and stabilizing grid demand.

Digital twins—virtual replicas of factory environments—also enable real-time simulations. Managers can test energy-saving scenarios digitally before implementing them in physical systems. These insights allow industries to make data-driven adjustments without risking operational disruption.

Measuring Energy Efficiency in Real Time

Tracking and verifying energy performance is critical for sustaining progress. Automation platforms measure energy per production unit, visualize trends, and calculate return on efficiency investments. Common benchmarks include kilowatt-hour per unit (kWh/unit) and the energy intensity index.

Many manufacturers adopt international frameworks such as ISO 50001, which standardize energy management practices. By integrating automation with these standards, companies ensure transparency and accountability. Consistent monitoring transforms energy management from a one-time audit into a continuous improvement process.

Challenges and Barriers to Adoption

High Initial Investment

Despite its clear benefits, one of the biggest obstacles to automation energy efficiency is upfront cost. Modernizing equipment, deploying smart sensors, and integrating control systems require substantial capital. For small and medium-sized manufacturers, this investment may seem daunting. However, studies show that the payback period for energy-efficient automation typically ranges between two and five years — far shorter than most heavy machinery lifecycles.

As technology prices decline and governments introduce green incentives, automation is becoming increasingly accessible. Financial support programs and carbon credit systems encourage industries to invest in efficiency rather than expansion alone.

Skills Gap and System Integration

Another challenge is the shortage of skilled professionals capable of managing smart industry systems. Technicians must now combine mechanical knowledge with data analytics and IT expertise. Without proper training, automation systems risk underperformance or misconfiguration.

Legacy systems also pose integration barriers. Many older machines were never designed for digital communication, making retrofitting a complex process. However, with modular IoT adapters and scalable control software, even traditional equipment can participate in energy-efficient automation networks.

The Future of Smart Industry and Sustainability

AI-Driven Optimization and Self-Learning Systems

The next wave of industrial innovation is self-learning automation. Artificial intelligence is already capable of analyzing vast datasets to predict energy demand, adjust workloads, and minimize waste. Future systems will operate semi-autonomously — balancing energy distribution, scheduling maintenance, and adapting to renewable energy fluctuations without human intervention.

Imagine a factory that automatically slows its operations when solar energy drops and ramps up when battery storage peaks. These capabilities redefine efficiency, making production resilient and environmentally adaptive.

Toward a Global Standard of Energy-Intelligent Manufacturing

As nations commit to carbon neutrality, automation energy efficiency will play a critical role in reshaping industrial policy. Governments and global organizations are promoting unified frameworks for energy-intelligent factories. Standardized reporting systems, cross-border knowledge sharing, and digital innovation hubs are driving this transformation forward.

The end goal is clear: to create manufacturing systems that think, adapt, and optimize continuously. When smart technology and sustainability converge, industry becomes not only more productive — but also more responsible.

Conclusion — Smarter Factories, Greener Future

Automation is no longer a luxury reserved for high-tech industries; it’s the foundation of future manufacturing. By combining intelligence with efficiency, automation allows companies to cut waste, save energy, and boost competitiveness simultaneously. The principles of green manufacturing and smart industry meet at this crossroads, where sustainability and profitability can coexist.

In an era defined by climate challenges and rapid technological progress, automation energy efficiency stands as a bridge to a sustainable industrial future. Smarter machines lead to cleaner production — and cleaner production leads to a stronger planet. The transformation is already underway, and those who adapt early will define the next era of manufacturing excellence.