Few companies have redefined modern manufacturing as boldly as Tesla. While most headlines focus on electric vehicles or stock volatility, a quieter revolution has been unfolding inside its factories. At the center of this transformation is tesla automation — a manufacturing philosophy built on robotics innovation, data intelligence, and smart manufacturing principles. More than just a production upgrade, Tesla’s automation strategy represents a blueprint for the future of industrial operations.

Why Tesla Automation Matters

Automation in manufacturing isn’t new. Car factories have used robotic arms for decades. What makes tesla automation different is its ambition. Tesla doesn’t simply automate isolated tasks; it attempts to automate the entire ecosystem — from stamping and welding to software diagnostics and predictive maintenance. Elon Musk once described the factory as “the machine that builds the machine,” signaling that Tesla sees manufacturing itself as a product worthy of innovation.

This mindset transforms automation from a cost-cutting tactic into a strategic advantage. Through advanced robotics innovation and tightly integrated smart manufacturing systems, Tesla aims to increase speed, consistency, and scalability in ways traditional manufacturers struggle to replicate.

The Evolution of Tesla Automation

From Traditional Assembly Lines to Hyper-Automation

Conventional automotive production relies on semi-automated assembly lines, where humans and robots share clearly defined roles. Tesla, however, pursued hyper-automation — integrating robotics into nearly every stage of production. The goal was precision and efficiency at a scale previously unseen in automotive manufacturing.

Unlike legacy manufacturers that gradually layered automation onto existing systems, Tesla designed many of its Gigafactories around automation from the start. This allowed the company to build facilities optimized for continuous material flow, robotic welding cells, and AI-enhanced inspection systems.

In many ways, tesla automation reflects the principles of modern smart manufacturing: interconnected machines, real-time data analysis, and digital control over physical production. Instead of reacting to issues after they occur, Tesla’s system seeks to anticipate and adjust processes dynamically.

Lessons from Early Failures

Yet the journey wasn’t smooth. During the Model 3 production ramp-up, Tesla famously encountered severe bottlenecks. Over-automation led to unexpected system fragility. Robots stalled. Processes jammed. Deadlines slipped. Elon Musk publicly admitted that “excessive automation” had been a mistake, emphasizing that humans remain essential to flexibility and problem-solving.

This period became a defining lesson in the evolution of tesla automation. It demonstrated that robotics innovation must complement — not replace — human expertise. The company recalibrated its approach, introducing more human oversight while maintaining high levels of automation in repetitive, precision-based tasks.

Robotics Innovation at Scale

How Tesla Uses Industrial Robotics

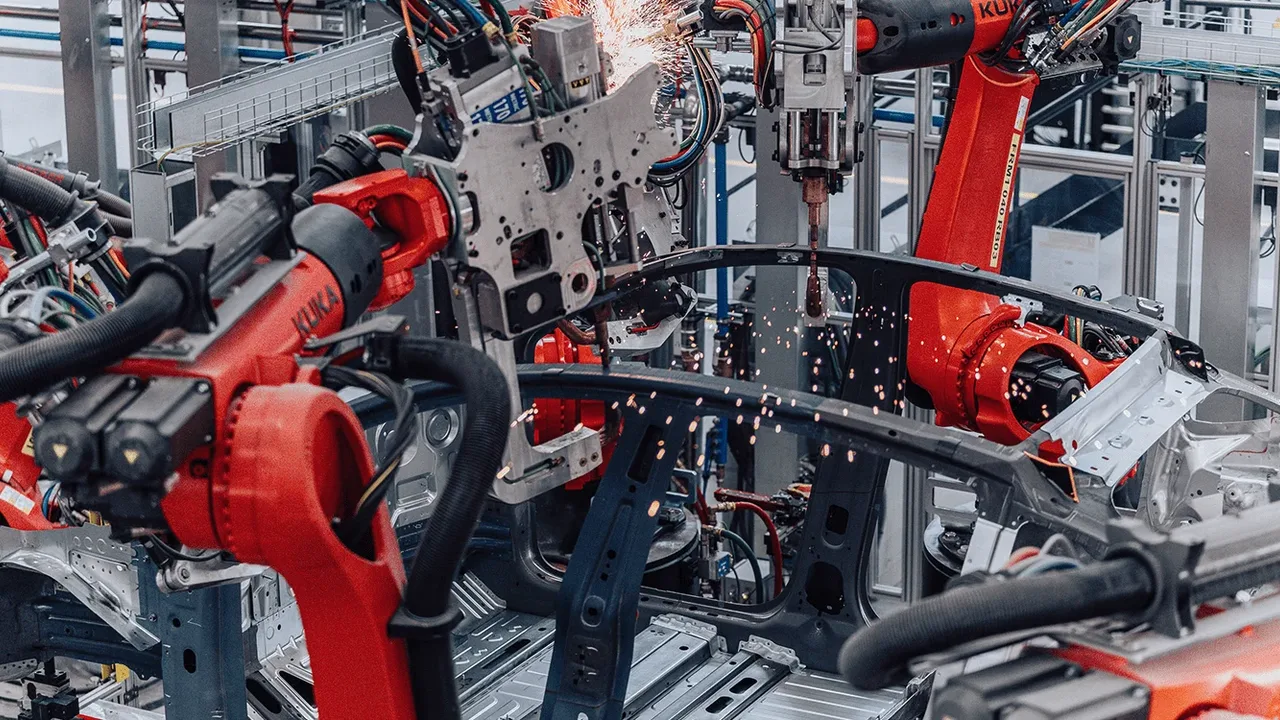

Today, Tesla’s factories are among the most automated automotive facilities in the world. Massive robotic arms handle welding, painting, stamping, and component assembly with remarkable precision. These machines operate continuously, minimizing downtime and ensuring consistent output.

Key applications of robotics innovation within Tesla include:

- Automated welding systems that improve structural consistency.

- Robotic painting lines that reduce material waste and increase coating precision.

- AI-powered vision systems for real-time quality inspection.

- Autonomous material handling using guided vehicles inside Gigafactories.

This ecosystem demonstrates how tesla automation integrates hardware and software seamlessly. Machines aren’t isolated units; they are nodes in a connected production network.

Integration of AI and Machine Learning

Beyond mechanical automation, Tesla applies artificial intelligence to optimize performance. Machine learning models analyze production data to identify inefficiencies, detect micro-defects, and predict equipment failures. Instead of waiting for breakdowns, systems trigger preventive maintenance alerts.

The impact of combining robotics innovation with AI can be summarized as follows:

| Traditional Manufacturing | Tesla Automation Model |

|---|---|

| Reactive maintenance | Predictive, AI-driven maintenance |

| Isolated robotic stations | Fully integrated robotic ecosystem |

| Manual defect detection | Computer vision quality inspection |

| Sequential process optimization | Real-time adaptive production control |

By aligning data analytics with smart manufacturing, Tesla reduces production variability and shortens iteration cycles. Updates to design or process parameters can be implemented rapidly across entire production lines.

Smart Manufacturing as a Competitive Advantage

Vertical Integration Strategy

Another defining element of tesla automation is vertical integration. Unlike many automakers that outsource battery production or rely heavily on suppliers, Tesla builds much of its technology in-house. Gigafactories combine battery cell production, vehicle assembly, and quality testing within one ecosystem.

This consolidation enhances smart manufacturing efficiency. Data flows between departments without friction, enabling design engineers to collaborate directly with production teams. When a design adjustment is required, manufacturing algorithms can recalibrate almost instantly.

Speed, Scalability, and Cost Control

Automation gives Tesla the ability to scale rapidly. Once a process is optimized, replicating it in new facilities becomes significantly easier. Robotics innovation ensures consistent output regardless of location, while AI-driven monitoring maintains quality standards across global sites.

In addition, tesla automation contributes to cost stability. Although upfront capital investment in robotics and AI systems is high, long-term operational efficiency reduces labor variability and waste. Over time, this strengthens competitive positioning in an increasingly price-sensitive EV market.

The broader lesson is clear: automation isn’t simply about replacing workers — it’s about redesigning production logic. By embedding intelligence into machines, companies can unlock continuous improvement rather than one-time optimization.

Data Is the Real Engine Behind Tesla Automation

Factory as a Living Data Platform

If robotics innovation forms the visible layer of tesla automation, data is the invisible engine driving it forward. Every robotic movement, weld precision point, and assembly sequence generates streams of operational data. Tesla treats its factories not merely as production sites but as living data platforms.

Sensors embedded across equipment collect information on temperature, vibration, cycle times, and defect rates. These data streams feed centralized analytics systems that continuously refine production performance. Instead of static manufacturing rules, smart manufacturing at Tesla adapts dynamically. When minor inefficiencies are detected, the system can recalibrate without halting the line.

This approach mirrors broader Industry 4.0 principles, where cyber-physical systems synchronize digital intelligence with physical operations. According to the World Economic Forum’s overview of Industry 4.0, advanced manufacturing depends on the integration of automation, artificial intelligence, and interconnected devices — a model that closely aligns with tesla automation strategy.

Feedback Loops Between Design and Production

One of the most powerful aspects of tesla automation is the feedback loop connecting engineering teams with the factory floor. In traditional automotive manufacturing, design changes may take months to implement due to fragmented supply chains and rigid processes. Tesla’s vertically integrated model compresses this cycle dramatically.

When production data reveals inefficiencies or improvement opportunities, engineers can update designs, modify software parameters, or recalibrate robotics systems rapidly. This iterative model allows Tesla to treat manufacturing as a constantly evolving system rather than a fixed structure.

Risks and Criticism of Tesla Automation

Over-Reliance on Robotics

Despite its strengths, tesla automation is not immune to risk. High levels of robotics innovation can introduce complexity that becomes difficult to manage. A single malfunctioning subsystem can cascade into broader production slowdowns. Hyper-automation demands sophisticated oversight and skilled technical teams capable of troubleshooting both mechanical and software-based issues.

Capital intensity is another challenge. Building highly automated Gigafactories requires massive upfront investment in robotics, AI infrastructure, and data architecture. For many companies, replicating Tesla’s scale may not be financially feasible.

Workforce Implications

The workforce implications of smart manufacturing are widely debated. Automation inevitably changes labor dynamics. While some repetitive roles diminish, new opportunities emerge in robotics maintenance, AI system management, and industrial data analytics.

Tesla’s experience suggests that tesla automation does not eliminate the need for people — it transforms their roles. Technicians, engineers, and software specialists become central to maintaining and evolving automated systems. The future workforce in highly automated factories will require hybrid skills combining mechanical knowledge with digital fluency.

What Other Industries Can Learn from Tesla Automation

Manufacturing Beyond Automotive

The principles behind tesla automation extend well beyond electric vehicles. Steel fabrication, electronics manufacturing, logistics, and even food processing can apply similar robotics innovation strategies. The key lesson is phased implementation. Rather than automating everything simultaneously, organizations should identify high-impact, repetitive processes where automation delivers immediate value.

Adopting smart manufacturing systems incrementally reduces risk and builds internal expertise. Over time, automation layers can integrate into a cohesive ecosystem similar to Tesla’s model.

Startups and SMEs

Smaller companies often assume that large-scale automation is reserved for global giants. However, the strategic lesson of tesla automation is not scale — it is mindset. Even startups can leverage robotics innovation in targeted ways: automated quality inspection, AI-powered inventory management, or predictive maintenance software.

The core idea is to treat automation as a strategic framework rather than a collection of machines. Data-driven decision-making, vertical integration where feasible, and continuous iteration are principles accessible to organizations of many sizes.

The Future of Tesla Automation

AI-Driven Autonomous Factories

Looking ahead, the next evolution of tesla automation may involve increasingly autonomous production environments. As AI algorithms mature, factories could adjust entire workflows based on demand forecasts, supply fluctuations, or performance metrics — with minimal human intervention.

Collaborative robotics, where humans and machines work side by side, will likely become standard. Instead of replacing workers, robotics innovation may augment their capabilities, handling precision tasks while humans focus on strategic and creative problem-solving.

Global Expansion and Replication

Tesla’s Gigafactory model demonstrates how smart manufacturing systems can be replicated globally. Standardized automation modules, combined with localized workforce training, allow rapid expansion while maintaining quality control. Each new facility benefits from lessons learned in previous locations, reinforcing a continuous improvement loop.

As automation technology becomes more affordable and accessible, the gap between highly automated leaders and traditional manufacturers may narrow. However, the strategic advantage will remain with organizations that integrate automation into their core identity rather than treat it as an afterthought.

Automation Is Strategy, Not Just Technology

The story of tesla automation is not simply about robots building cars. It is about redefining how industries think about production itself. Through robotics innovation, AI integration, and smart manufacturing principles, Tesla transformed the factory into a dynamic, data-driven ecosystem.

The most important lesson for businesses is balance. Automation must enhance human expertise, not attempt to erase it. Companies that combine technological ambition with operational realism will unlock sustainable competitive advantages.

Ultimately, tesla automation illustrates that the future of manufacturing belongs to organizations willing to rethink processes from the ground up. In a world defined by speed, scalability, and intelligence, automation is no longer optional — it is strategic.