The digital transformation sweeping across industries is redefining how machines, data, and people interact. At the center of this revolution is the industrial IoT future — a connected ecosystem that enables factories, supply chains, and utilities to communicate in real time. As connectivity deepens, the Industrial Internet of Things (IIoT) is not just improving efficiency; it’s reshaping how entire industries operate and compete.

Introduction — The Connected Revolution

From automotive plants to energy facilities, businesses are rapidly embracing smart connectivity to monitor performance, optimize workflows, and predict failures before they happen. The concept of IIoT extends far beyond basic automation; it represents a fully networked industrial world where every piece of equipment becomes a data-generating asset. This shift toward a connected manufacturing ecosystem marks one of the most significant leaps since the first industrial revolution.

Through sensors, cloud computing, and analytics, the industrial IoT future aims to eliminate silos between machines and decision-makers. Data no longer sits idle — it informs real-time actions, guiding everything from maintenance schedules to energy optimization. The industries that successfully harness this connectivity are positioning themselves for long-term resilience and competitiveness.

Understanding the Industrial IoT Ecosystem

What Is Industrial IoT (IIoT)?

The Industrial Internet of Things, or IIoT, is a subset of the broader Internet of Things, specifically designed for heavy industry. It connects machinery, sensors, and control systems to collect and analyze operational data. While consumer IoT powers smart homes and devices, IIoT fuels smart factories, logistics centers, and energy grids. The result is an industrial ecosystem where intelligence is distributed across every level of operation.

Through networked data sensors, IIoT continuously monitors equipment performance, tracks environmental conditions, and identifies anomalies. For instance, vibration sensors on turbines can predict mechanical wear weeks in advance, preventing costly breakdowns. This capability transforms maintenance from reactive to predictive, saving time, money, and materials.

Core Components of an IIoT Network

Every successful industrial IoT system is built on four key pillars:

- Data sensors and devices – Collect information from machines, materials, and the environment.

- Connectivity – Transmits data using networks like Wi-Fi, 5G, or industrial Ethernet.

- Data processing and analytics – Converts raw data into actionable insights, often through edge computing.

- Automation and control – Executes decisions, adjusting operations in real time to improve performance.

Together, these elements create a feedback loop where data constantly circulates between devices, cloud platforms, and human operators. According to insights from Siemens, industries adopting integrated IIoT systems have achieved up to 20% improvement in productivity and 30% reduction in downtime, proving how transformative connected ecosystems can be.

The Impact of IIoT on Manufacturing

Connected Manufacturing in Action

In modern factories, connected manufacturing enables production lines to adjust instantly to real-time conditions. If one machine slows down or overheats, the system automatically redistributes workloads or adjusts output to maintain flow. This orchestration is made possible by thousands of embedded sensors that continuously feed data into centralized platforms.

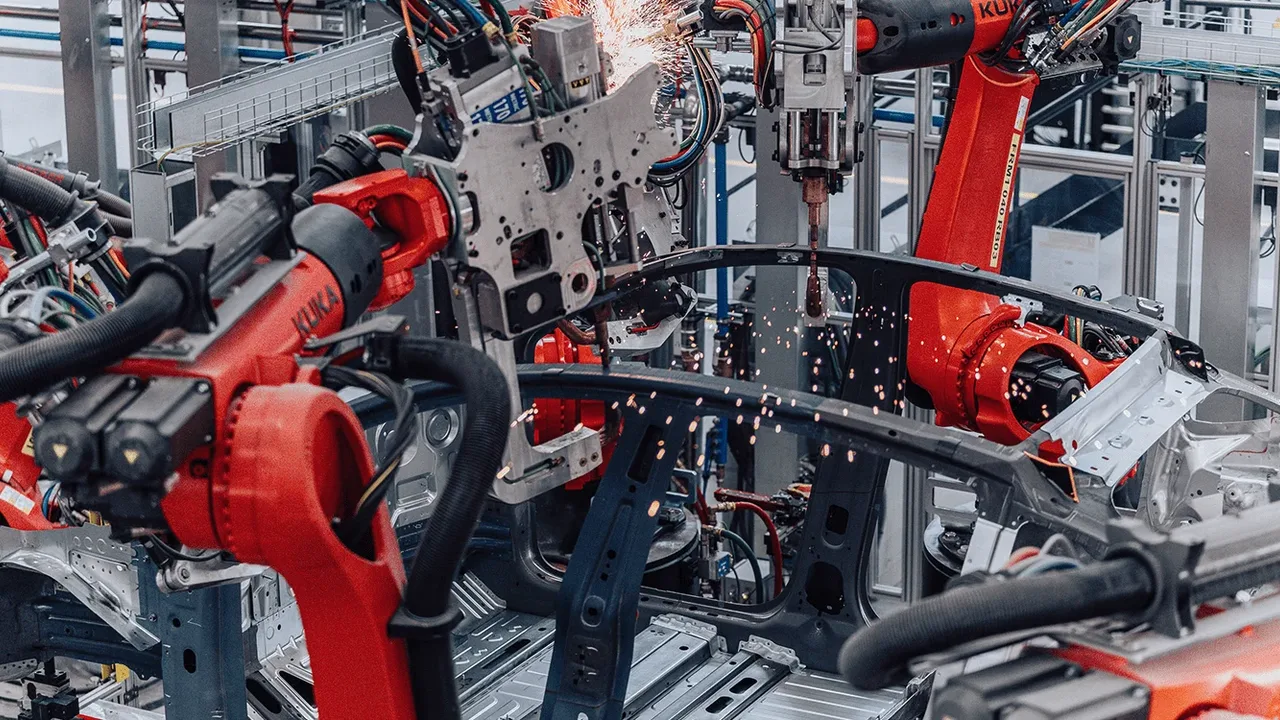

For example, a steel plant using IIoT-enabled systems can track the temperature, composition, and flow of molten metal in real time. The data allows supervisors to optimize furnace operations, improve yield, and reduce waste. Similarly, in automotive assembly, robotic arms equipped with sensors can coordinate movement with human workers safely and efficiently, minimizing the risk of collisions and errors.

Improving Quality and Efficiency

Beyond automation, the industrial IoT future emphasizes intelligent decision-making. Quality control processes that once depended on manual inspection are now enhanced by AI-powered vision systems capable of identifying microscopic defects at production speed. This results in higher consistency and reduced material loss.

IIoT also streamlines coordination between departments through digital integration. Production data syncs with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), ensuring seamless communication from the factory floor to executive dashboards. By closing the gap between physical and digital operations, industries are achieving unprecedented visibility across their supply chains.

Industrial IoT and Data Intelligence

From Raw Data to Actionable Insights

The explosion of industrial data is both an opportunity and a challenge. Every connected machine, conveyor, or sensor generates a continuous stream of data. The key lies in transforming that information into insight. Artificial intelligence and machine learning algorithms sift through this data to detect trends, predict outcomes, and suggest improvements before humans even realize a problem exists.

For instance, data from a network of vibration sensors may reveal subtle fluctuations indicating early-stage bearing failure. By acting early, maintenance teams can avoid unplanned downtime and extend asset lifespan. These proactive interventions demonstrate how the industrial IoT future bridges analytics with tangible business outcomes.

Cybersecurity Challenges and Data Privacy

While IIoT connectivity unlocks efficiency, it also expands the threat surface for cyberattacks. As industrial systems connect to the cloud, they become potential targets for breaches that could disrupt production or expose proprietary data. Cybersecurity is therefore central to the success of IIoT adoption.

Organizations are increasingly investing in advanced encryption, multi-factor authentication, and zero-trust architectures to secure communication between devices. Continuous monitoring and anomaly detection are becoming standard practices, ensuring that even in highly connected environments, data integrity and privacy remain protected.

Emerging Trends Shaping the Industrial IoT Future

Edge and Cloud Computing Integration

The future of IIoT lies in balancing data processing between the edge and the cloud. Edge computing allows sensors and devices to process information locally, reducing latency and bandwidth requirements. This capability is crucial for time-sensitive operations, such as automated welding or precision machining, where milliseconds can impact quality. The cloud, meanwhile, provides scalable storage and advanced analytics, enabling deeper insights and long-term optimization.

By combining both models, industries gain the flexibility of local control with the intelligence of global analytics—an architecture that defines the evolving landscape of connected manufacturing.

5G Connectivity and Real-Time Communication

Among the most transformative forces shaping the industrial IoT future is 5G technology. With ultra-low latency and massive data bandwidth, 5G enables instant communication between sensors, machines, and control systems. This advancement allows factories to coordinate hundreds of automated devices simultaneously, achieving synchronization that was once impossible.

In large manufacturing plants, 5G networks power autonomous mobile robots that navigate production floors, delivering materials and components with precision. In logistics, they enable real-time tracking of shipments and predictive routing to reduce delivery times. By connecting every asset within an industrial ecosystem, 5G ensures that decisions can be made in milliseconds — a critical factor for safety and efficiency in high-speed operations.

Sustainability and Smart Factories

Beyond productivity, IIoT technologies play a crucial role in advancing sustainability goals. Smart factories equipped with data sensors can monitor power consumption, optimize HVAC systems, and automatically shut down idle equipment. These small adjustments collectively reduce energy use and emissions across global operations. Manufacturers are also leveraging IIoT to track water usage, waste generation, and carbon emissions in real time — turning environmental responsibility into measurable data.

In fact, many companies now integrate sustainability dashboards directly into their IIoT platforms, allowing them to visualize progress and align with ESG (Environmental, Social, and Governance) reporting standards. The industrial IoT future is not only about efficiency but also about building a more transparent, responsible industrial ecosystem.

Barriers to Adoption and Future Opportunities

Implementation Challenges

Despite its promise, the journey toward a fully connected industry is not without obstacles. The initial cost of deploying IIoT systems — from sensors to cloud infrastructure — can be high, particularly for small and medium-sized enterprises. Integration with legacy equipment is another major challenge, as older machines were not designed for digital connectivity. Interoperability remains a critical issue, with multiple vendors and platforms often struggling to communicate seamlessly.

Another challenge lies in workforce readiness. The transition to smart factories demands new skills in data analytics, cybersecurity, and system integration. Companies must invest in training and reskilling employees to operate, interpret, and maintain IIoT systems effectively.

Global Market Growth and Industry Adoption

Despite these barriers, the global market for industrial IoT continues to expand rapidly. According to industry forecasts, the IIoT sector is expected to surpass USD 1 trillion within the next decade. Key industries driving this growth include manufacturing, energy, logistics, and healthcare — all seeking real-time data visibility and automation efficiency.

Asia, Europe, and North America remain the largest adopters, but emerging markets are catching up quickly. Government initiatives promoting digital transformation and smart infrastructure are accelerating adoption rates. The combination of connected manufacturing, advanced analytics, and sustainability objectives ensures that IIoT will continue to shape the next wave of industrial modernization.

Real-World Examples of Industrial IoT Transformation

Real-world adoption of the industrial IoT future provides a glimpse into its potential impact. In one case, a global automotive manufacturer implemented IIoT sensors across its assembly lines to track vibration, pressure, and temperature data in real time. The system reduced unplanned downtime by 40% within the first year.

Similarly, an energy company integrated IIoT and cloud analytics to monitor turbine efficiency across multiple wind farms. Through predictive maintenance, they were able to increase output and extend equipment lifespan, leading to millions in cost savings. These success stories prove that when implemented effectively, IIoT delivers both economic and environmental advantages.

Meanwhile, in logistics and supply chain management, connected devices track cargo conditions such as temperature and humidity throughout transport. This level of traceability ensures quality control in industries like pharmaceuticals and food distribution — sectors where precision and compliance are paramount.

The Road Ahead — Building a Smarter Industrial World

As technologies mature, the industrial IoT future will continue to blur the line between digital and physical operations. Future factories will act more like living ecosystems — self-adjusting, learning, and evolving based on continuous data feedback. Artificial intelligence will become an embedded partner in decision-making, enhancing human judgment with predictive accuracy.

In this next phase, companies will need to prioritize interoperability, cybersecurity, and sustainability equally. Collaboration between hardware manufacturers, software developers, and governments will define how rapidly the world transitions toward an intelligent industrial economy.

At its core, the evolution of IIoT is about connection — not just between machines but between ideas, industries, and innovations. It is a revolution driven by insight, designed for efficiency, and guided by responsibility. The future of industrial IoT is not merely connected; it’s conscious.

Conclusion — Engineering Intelligence for Tomorrow

The journey toward a data-driven industrial era is already underway. The industrial IoT future promises unprecedented productivity, predictive insight, and sustainability at scale. But its real power lies in the ability to make industries adaptive — transforming every machine into a communicator and every process into a source of knowledge.

As the Fourth Industrial Revolution unfolds, organizations that embrace this transformation will redefine efficiency, innovation, and competitiveness. The factories of tomorrow will not just produce goods — they will produce data, intelligence, and resilience for the global economy.