For decades, industrial operations relied on a simple rule: fix equipment when it breaks. This reactive approach worked in slower production environments, but in today’s high-speed, data-driven economy, downtime can cost thousands—or even millions—of dollars per hour. As industries adopt automation and digital transformation, predictive maintenance has emerged as a powerful strategy that changes how companies manage machinery, risk, and performance.

Instead of waiting for failure, predictive maintenance uses data, analytics, and ai sensors to anticipate issues before they escalate. Combined with smart equipment and machine learning algorithms, this approach shifts maintenance from a cost center to a strategic advantage. It’s not just about repairs anymore—it’s about continuous optimization.

The End of Reactive Maintenance

Traditional maintenance models typically fall into two categories:

- Reactive maintenance – Repairing machines only after breakdown occurs.

- Preventive maintenance – Performing scheduled inspections or part replacements regardless of actual condition.

While preventive maintenance reduces unexpected failures, it often leads to unnecessary servicing and higher labor costs. Reactive maintenance, on the other hand, increases risk and operational disruption. Neither model fully leverages the capabilities of modern data systems.

This is where predictive maintenance stands apart. By continuously monitoring equipment conditions through ai sensors and analytics platforms, industries can forecast mechanical failures with impressive accuracy. Instead of guessing when a machine might fail, companies now rely on real-time data insights to make informed decisions.

What Is Predictive Maintenance?

Definition and Core Concept

Predictive maintenance is a data-driven strategy that monitors equipment performance and predicts potential failures before they happen. Unlike preventive maintenance, which operates on fixed schedules, predictive maintenance analyzes actual machine conditions. This reduces unnecessary interventions and focuses attention only when risk indicators appear.

The concept relies heavily on continuous data capture and algorithm-based diagnostics. Machines equipped with ai sensors collect information such as vibration levels, temperature changes, pressure fluctuations, and acoustic signals. These data streams feed into machine learning models that detect patterns associated with wear, fatigue, or malfunction.

How Predictive Maintenance Works

The predictive maintenance process typically follows a structured workflow:

| Step | Process | Outcome |

|---|---|---|

| 1 | Data collection via ai sensors | Real-time monitoring of equipment health |

| 2 | Data processing through analytics platforms | Pattern recognition and anomaly detection |

| 3 | Machine learning evaluation | Prediction of failure timelines |

| 4 | Automated alerts | Targeted maintenance scheduling |

Instead of replacing components prematurely, predictive maintenance ensures interventions occur only when needed. This precision reduces waste and extends equipment lifespan.

The Technology Behind Predictive Maintenance

AI Sensors and Real-Time Data

At the core of predictive maintenance lies advanced sensor technology. AI sensors are capable of capturing micro-level changes in machine behavior. For example, subtle vibration shifts in a motor may signal bearing wear long before visible damage occurs. Temperature anomalies might indicate lubrication issues, while pressure deviations could reveal leaks or blockages.

These sensors are often connected to cloud-based systems or edge computing platforms, enabling immediate analysis. Continuous monitoring eliminates blind spots that traditional inspections might miss. By feeding real-time data into intelligent systems, predictive maintenance becomes both proactive and precise.

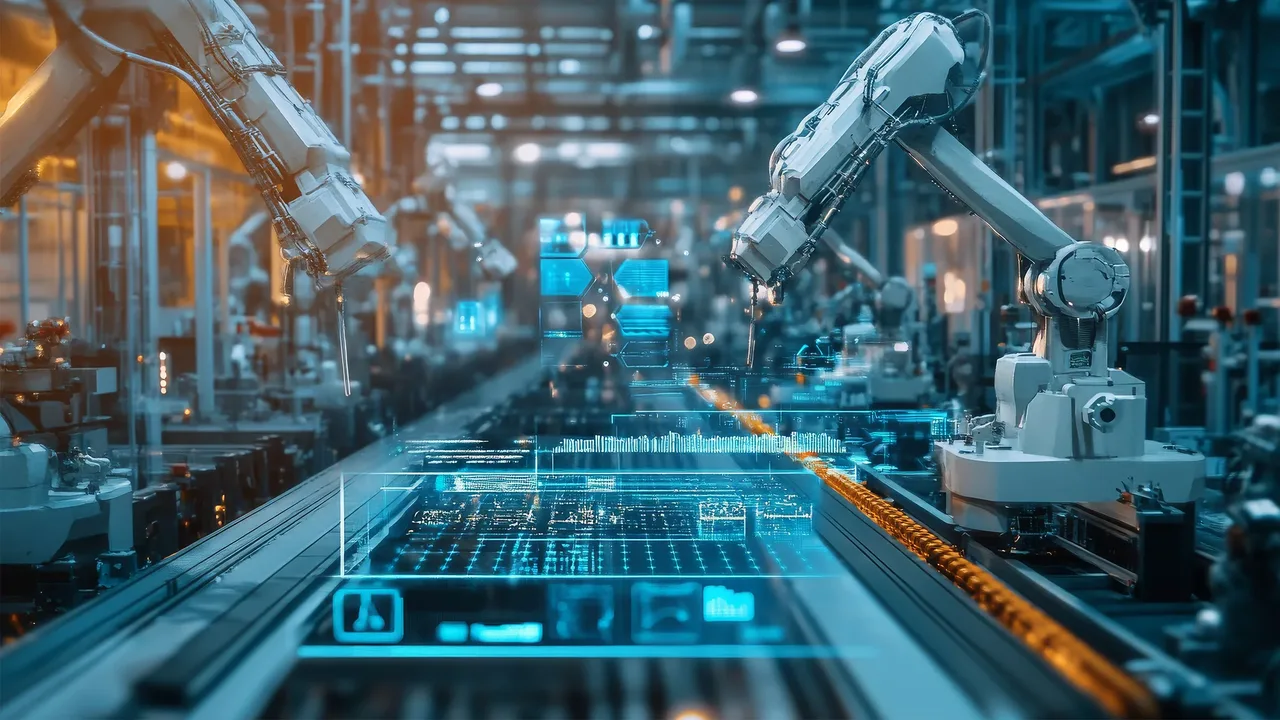

Industrial IoT networks further enhance this ecosystem. Through interconnected smart equipment, machines communicate performance metrics to centralized dashboards. Managers can visualize equipment health across entire facilities, making strategic maintenance decisions with confidence.

Smart Equipment and Machine Learning

Smart equipment takes predictive maintenance to the next level. Unlike conventional machinery, smart equipment integrates embedded processors, connectivity modules, and diagnostic software. These systems can self-report performance metrics and even adjust operations automatically when minor inefficiencies are detected.

Machine learning algorithms analyze historical and real-time data to establish baseline performance patterns. When deviations occur, the system flags them as potential issues. Over time, predictive models become increasingly accurate, adapting to the specific conditions of each machine.

This synergy between smart equipment and predictive maintenance reduces reliance on manual inspections. It also minimizes human error, ensuring consistent monitoring regardless of staffing levels or shift changes.

Benefits of Predictive Maintenance in Industry

Reduced Downtime and Cost Savings

Unplanned downtime is one of the most expensive challenges in industrial operations. Production halts, delayed shipments, and emergency repairs create ripple effects throughout supply chains. Predictive maintenance significantly reduces these disruptions by identifying problems early.

Studies across manufacturing sectors show that predictive maintenance can:

- Reduce maintenance costs by up to 25%

- Decrease equipment breakdowns by nearly 70%

- Extend asset lifespan by 20–40%

These improvements translate into measurable financial returns. By replacing parts only when performance data demands it, companies avoid both over-maintenance and catastrophic failure.

Improved Safety and Risk Management

Equipment failures don’t just affect productivity—they can pose serious safety risks. Overheated systems, mechanical fractures, or pressure leaks may endanger workers and facilities. Predictive maintenance enhances safety by identifying warning signs before dangerous thresholds are reached.

Through ai sensors and continuous monitoring, risk-prone components are flagged early. Maintenance teams can intervene under controlled conditions rather than reacting to emergencies. This proactive strategy supports regulatory compliance and strengthens workplace safety culture.

Energy Efficiency and Sustainability

Another overlooked advantage of predictive maintenance is improved energy efficiency. Machines operating under optimal conditions consume less power. Misaligned components, worn bearings, or overheating systems typically draw excess energy. By maintaining performance balance, predictive maintenance reduces waste and contributes to sustainability goals.

In a world increasingly focused on ESG performance and carbon reduction, predictive maintenance supports environmental responsibility. Smart equipment running efficiently lowers emissions and optimizes resource usage across industrial ecosystems.

Industry Applications of Predictive Maintenance

Manufacturing and Production Lines

In manufacturing environments, equipment reliability directly determines output volume and profitability. Robotic arms, conveyor systems, CNC machines, and automated assembly lines operate continuously under heavy loads. Even minor mechanical failures can halt entire production chains.

By implementing predictive maintenance, manufacturers gain real-time visibility into machine performance. AI sensors monitor vibration levels, torque, lubrication conditions, and temperature fluctuations. When abnormal patterns emerge, alerts are triggered before production is disrupted. This proactive strategy allows maintenance teams to intervene during scheduled downtime rather than during peak operations.

Factories equipped with smart equipment also benefit from integrated dashboards that display asset health across multiple production zones. Maintenance becomes strategic rather than reactive, aligning with lean manufacturing and Industry 4.0 objectives.

Energy and Utilities

The energy sector depends on the continuous operation of turbines, transformers, pipelines, and grid systems. Failures in these systems can have large-scale consequences, affecting entire communities or industrial clusters.

Predictive maintenance plays a crucial role here. Wind turbines, for example, use ai sensors to track blade vibration and rotational stability. Power plants monitor pressure and temperature variations to detect inefficiencies before breakdowns occur. According to data from the U.S. Department of Energy, predictive analytics in wind energy systems significantly reduces maintenance costs and improves operational uptime—demonstrating how data-driven insights enhance infrastructure resilience.

In utilities, predictive maintenance also supports grid stability. By anticipating transformer overloads or cable degradation, operators reduce outage risks and enhance service reliability.

Transportation and Logistics

Transportation systems—including rail networks, aviation fleets, and shipping operations—depend on equipment precision. Mechanical failure in these sectors doesn’t just cause delays; it can compromise safety and regulatory compliance.

Airlines increasingly rely on predictive maintenance to monitor engine health using ai sensors embedded in turbines. Rail operators analyze wheel vibration and track conditions to prevent derailments. Logistics companies integrate smart equipment diagnostics into fleet management systems, predicting engine wear or brake failure before incidents occur.

In each case, predictive maintenance ensures smoother operations and protects both passengers and cargo.

Challenges and Implementation Barriers

Initial Investment and System Integration

Despite its advantages, adopting predictive maintenance requires upfront investment. Installing ai sensors, integrating data platforms, and upgrading legacy machinery can be costly. Small and mid-sized enterprises may hesitate due to perceived financial risk.

Integration complexity also poses challenges. Older equipment may lack compatibility with modern data networks, requiring retrofitting or phased modernization strategies. However, as sensor technology becomes more affordable and scalable, these barriers continue to decline.

Data Security and Workforce Skills

Data-driven systems introduce cybersecurity concerns. Industrial IoT networks connected to cloud platforms must be protected against unauthorized access. Without robust encryption and monitoring, sensitive operational data could be exposed.

Workforce adaptation is another critical factor. Predictive maintenance depends on skilled technicians capable of interpreting analytics dashboards and machine learning insights. Companies must invest in training programs to ensure employees understand both mechanical systems and digital tools.

The Future of Predictive Maintenance

Autonomous Industrial Systems

The next stage of predictive maintenance goes beyond alerts—it moves toward autonomous correction. In advanced facilities, smart equipment can adjust operating parameters automatically when minor deviations are detected. For example, lubrication systems may self-regulate when sensors identify friction increases.

As machine learning algorithms evolve, predictive maintenance systems will continuously refine their accuracy. They will learn from each intervention, improving future forecasts and reducing false positives.

From Maintenance to Performance Optimization

The real transformation lies in shifting from maintenance to performance optimization. Predictive maintenance doesn’t simply prevent failure; it enhances productivity. By analyzing operational trends, companies can identify inefficiencies in energy usage, component wear patterns, and workflow alignment.

This broader view integrates predictive maintenance into enterprise strategy. Instead of being a back-end technical function, it becomes central to competitive advantage. Industries that leverage ai sensors and smart equipment effectively will operate with greater agility, reliability, and sustainability.

A Smarter Industrial Future

Industrial success today depends on precision, efficiency, and resilience. Predictive maintenance redefines how organizations approach equipment management, transforming maintenance from a reactive obligation into a predictive science. By combining ai sensors, smart equipment, and machine learning analytics, industries reduce downtime, enhance safety, and optimize energy use.

The shift toward predictive maintenance signals a broader digital transformation across sectors. As technology advances and adoption widens, this strategy will become not just an innovation—but a standard expectation for modern industry. Companies that embrace predictive maintenance today position themselves at the forefront of operational excellence tomorrow.