Industrial waste has long been one of the biggest hidden costs in manufacturing. Every defective product, excess material cut, or unnecessary machine downtime represents not only financial loss but also environmental impact. As sustainability becomes a core business priority, manufacturers are looking beyond traditional efficiency methods and turning toward artificial intelligence. This shift has given rise to a powerful concept: ai waste reduction.

Artificial intelligence is no longer limited to data analytics dashboards or experimental projects. Today, AI systems actively monitor production lines, detect anomalies, predict failures, and optimize processes in real time. The result is a smarter factory that produces more with less—less material, less energy, and less waste.

The Growing Waste Problem in Manufacturing

Manufacturing waste comes in many forms. Some are obvious, such as scrap metal or defective components. Others are less visible, including excess energy consumption, unnecessary rework, and inefficient machine operation. Together, these forms of waste add up to billions of dollars in losses each year.

Traditional waste reduction strategies rely heavily on manual inspections, historical averages, and reactive problem-solving. While these approaches can help, they often fail to address the root causes of inefficiency. This is where ai waste reduction changes the equation. Instead of reacting after waste occurs, AI enables factories to predict and prevent waste before it happens.

Understanding Industrial Waste

Types of Waste in Factories

Before exploring how AI solves the problem, it is important to understand the main categories of industrial waste:

- Material scrap: Excess raw materials or defective parts.

- Defective products: Items that fail quality standards.

- Energy waste: Unnecessary power consumption.

- Water waste: Inefficient use of cooling and processing water.

Each type of waste represents an opportunity for improvement. When addressed together, they can dramatically increase efficiency.

Why Traditional Methods Fall Short

Most conventional waste reduction efforts depend on periodic audits and human observation. These methods are limited by scale and speed. Humans cannot continuously monitor thousands of data points across complex production lines.

AI systems, on the other hand, analyze massive volumes of data in real time. They identify patterns and correlations that would be impossible to detect manually. This capability makes AI uniquely suited for modern manufacturing environments.

What Is AI Waste Reduction?

Defining AI in Manufacturing

AI in manufacturing refers to the use of machine learning, computer vision, and advanced analytics to improve production processes. These technologies allow machines to learn from data, recognize patterns, and make decisions without explicit programming.

In the context of ai waste reduction, this means identifying inefficiencies, predicting defects, and optimizing operations automatically.

How AI Identifies Inefficiencies

AI systems continuously collect data from sensors, cameras, and machines. They compare real-time conditions against optimal performance models. When deviations occur, the system flags them or automatically adjusts parameters.

This closed-loop feedback system transforms factories from static operations into dynamic, self-improving environments.

AI-Powered Quality Control

Computer Vision for Defect Detection

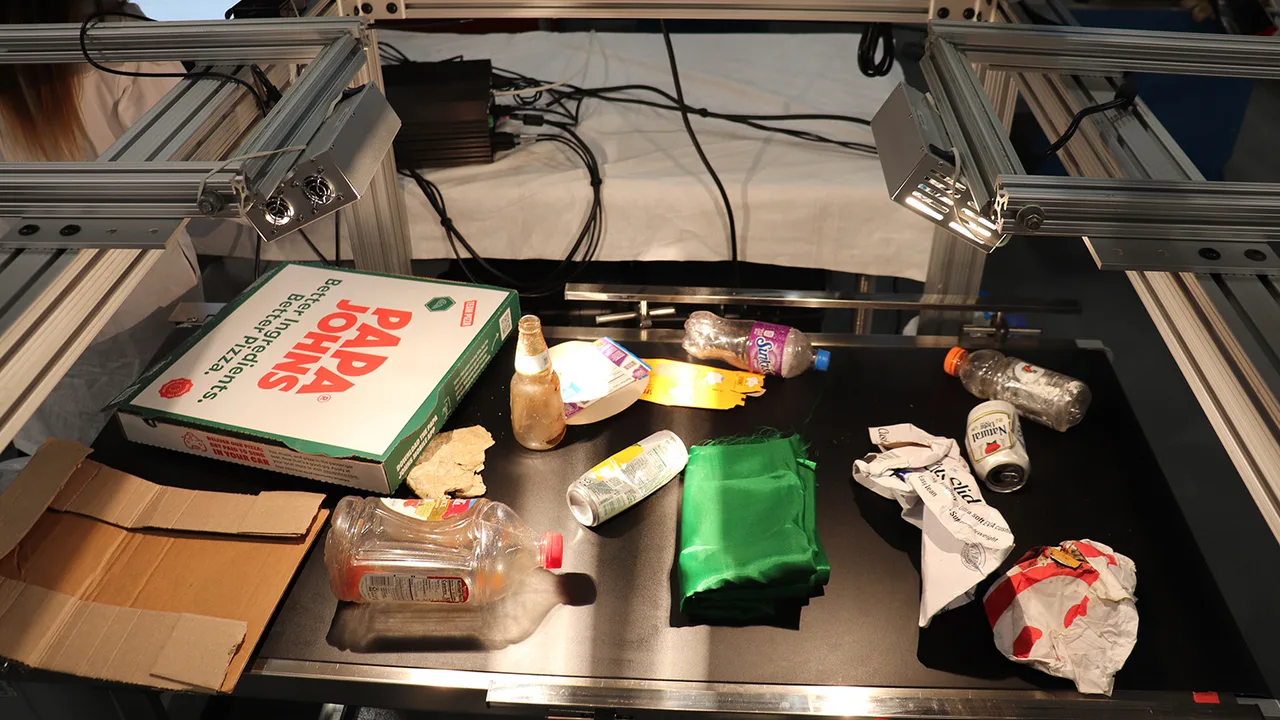

One of the most impactful applications of AI is computer vision. Cameras combined with AI algorithms inspect products as they move along the production line. These systems can detect tiny cracks, surface imperfections, and dimensional errors that human inspectors might miss.

Because inspection happens in real time, defective items are removed immediately. This prevents flawed components from moving further down the line, where they would consume additional resources.

Reducing Rework and Scrap

Early detection dramatically reduces rework and scrap. Instead of discovering defects at the final stage, manufacturers catch issues at the source.

This approach not only cuts material waste but also improves throughput and consistency.

Predictive Maintenance and Waste Prevention

Equipment Failure as a Source of Waste

Unexpected equipment failures often lead to large amounts of waste. Machines may produce out-of-spec products before shutting down, or entire batches may be lost.

Downtime also disrupts schedules, leading to rushed production and increased error rates.

How AI Predicts Breakdowns

AI models analyze vibration, temperature, and performance data from machines. By recognizing early warning signs, they predict failures before they occur.

Maintenance teams can then service equipment proactively, preventing breakdowns and the waste associated with them.

AI and Smart Process Optimization

Optimizing Production Parameters

Every manufacturing process has optimal ranges for temperature, pressure, speed, and material flow. AI continuously fine-tunes these parameters to maintain peak performance.

This level of precision reduces variability, which directly translates into lower defect rates.

Integration with Automation Systems

AI becomes even more powerful when integrated with automation systems. Robots, conveyors, and programmable logic controllers can respond instantly to AI recommendations.

This integration creates a fully responsive production environment that adapts in real time.

Supporting Sustainable Production

Material Efficiency

By optimizing cutting patterns, mixing ratios, and assembly sequences, AI minimizes material usage. Less material in means less waste out.

Energy and Resource Optimization

AI identifies opportunities to reduce electricity, gas, and water consumption without compromising output. These improvements support broader goals of sustainable production.

Lower resource usage benefits both the environment and the bottom line.

Case Examples of AI Waste Reduction in Factories

Across multiple industries, manufacturers are already seeing measurable results from implementing ai waste reduction. In electronics manufacturing, computer vision systems inspect circuit boards at high speed, identifying micro-defects that would previously go unnoticed. This reduces scrap and prevents defective components from entering final assembly.

In automotive plants, AI models analyze sensor data from welding robots and painting systems. When deviations occur, the system adjusts parameters in real time, preventing rework and reducing material consumption. Metal fabrication facilities use AI to optimize cutting patterns, minimizing leftover scrap while maintaining dimensional accuracy.

These examples highlight a common theme: AI does not replace human expertise—it augments it. Engineers and operators gain deeper insight into processes and can make better decisions faster.

Business Benefits Beyond Sustainability

Cost Reduction

The most immediate benefit of ai waste reduction is lower operating cost. Less scrap means fewer raw materials purchased. Fewer defects mean less rework and less labor wasted. Predictive maintenance reduces downtime and extends equipment life.

Over time, these savings compound. What begins as a sustainability initiative quickly becomes a strong financial strategy.

Consistency and Scalability

AI-driven processes deliver consistent quality. Variability is one of the biggest enemies of efficiency, and AI excels at controlling it.

Once an optimized model is in place, it can be scaled across multiple production lines or facilities. This allows organizations to replicate best practices quickly without reinventing processes.

Challenges in Implementing AI for Waste Reduction

Data Quality and Infrastructure

AI is only as good as the data it receives. Incomplete, noisy, or inconsistent data can limit performance. Factories must invest in reliable sensors, connectivity, and data management systems.

While this requires upfront effort, it also creates a digital foundation that supports future innovations.

Skills and Change Management

Introducing AI changes how people work. Employees may need training to interpret AI insights and adjust workflows. Resistance to change is natural, but clear communication and involvement help ease the transition.

Successful implementations treat AI as a collaborative tool rather than a replacement for human judgment.

The Role of Standards and Best Practices

Manufacturers increasingly align their sustainability initiatives with recognized frameworks and guidelines. International standards related to environmental management and industrial efficiency provide structure for measuring and improving performance, such as those referenced by the International Organization for Standardization.

Aligning ai waste reduction projects with these frameworks helps organizations benchmark progress and demonstrate credibility.

The Future of AI Waste Reduction

The next generation of factories will move toward self-optimizing systems. AI models will not only detect problems but also propose and implement solutions automatically.

- Digital twins: Virtual replicas of factories that simulate changes before deployment.

- Closed-loop optimization: Continuous learning and adjustment.

- Circular manufacturing: Designing products and processes for reuse and recycling.

As technology mature, waste will increasingly be treated as a design flaw rather than an unavoidable byproduct.

Conclusion

Industrial waste is not just an environmental issue—it is a business inefficiency. By embracing ai waste reduction, manufacturers gain the ability to see, understand, and control their processes at an unprecedented level.

AI-powered quality control, predictive maintenance, and smart optimization create factories that are leaner, cleaner, and more resilient. The path to sustainable production is not about doing less—it is about doing things smarter.