Across Asia’s rapidly growing cities, steel is doing more than holding up buildings — it’s shaping skylines, economies, and cultural identity. The modern steel megastructure has become a defining symbol of progress, precision, and power. From record-breaking skyscrapers to sprawling airports and bridges, these colossal frameworks represent the pinnacle of engineering marvels and human ambition.

Introduction — Asia’s Era of Monumental Construction

In just a few decades, Asia has transformed into the world’s most dynamic hub of architectural innovation. Nations such as China, South Korea, Singapore, and Malaysia have turned cities into laboratories of scale and creativity. The rise of the steel megastructure is at the heart of this revolution, enabling engineers and architects to build higher, faster, and more sustainably than ever before.

Fueled by urbanization, economic growth, and technological breakthroughs, Asia’s construction industry has mastered the use of steel as both a structural and aesthetic element. Each tower, bridge, and stadium now tells a story of design evolution — where functionality meets beauty, and where high-rise design merges with national pride.

What Defines a Steel Megastructure

The Core Principles of Megastructure Engineering

At its essence, a steel megastructure is an engineered system capable of carrying enormous loads while maintaining flexibility and resilience. These structures rely on modular frameworks, long-span trusses, and space frame systems that distribute forces efficiently. The result is a framework that supports massive weight without compromising aesthetics or spatial efficiency.

Unlike traditional reinforced concrete, steel offers higher strength-to-weight ratios and easier adaptability. This flexibility allows architects to create open interiors, curved façades, and hybrid building functions that push conventional boundaries. Whether supporting observation decks at 600 meters or terminal roofs spanning hundreds of meters, steel remains unmatched in versatility.

The Role of Material Science

Advances in material science have redefined the capabilities of steel in modern construction. Today’s engineers employ high-tensile alloys, corrosion-resistant coatings, and advanced welding methods that extend the lifespan of large projects. Innovations in fatigue resistance and energy absorption ensure that megastructures can withstand earthquakes, wind storms, and even typhoons common in Asia’s coastal regions.

Moreover, these materials enable lighter designs that consume less steel per structure — aligning with the sustainability goals now central to urban development. The result is a new generation of megastructures that are as efficient as they are awe-inspiring.

The Evolution of High-Rise Design in Asia

From Function to Form — The Rise of Landmark Skylines

Asia’s skylines are no longer defined merely by height but by harmony. The evolution of high-rise design reflects a synthesis of art, technology, and identity. Cities such as Shanghai, Kuala Lumpur, and Seoul have developed iconic architectural landmarks that double as national symbols.

The Shanghai Tower, for instance, spirals upward with a twisting steel-and-glass façade designed to reduce wind load by 24%. The Petronas Towers remain a testament to Malaysia’s post-industrial ambition, combining Islamic design principles with structural steel innovation. Similarly, the Lotte World Tower in Seoul integrates cultural motifs with advanced damping systems, demonstrating how structural intelligence can coexist with artistic expression.

The Engineering Behind Vertical Cities

Engineering a steel megastructure isn’t just about vertical growth; it’s about complexity. Today’s skyscrapers often function as miniature cities — combining residential, commercial, and leisure zones within one integrated system. Steel’s ability to support wide, column-free spaces makes these multi-purpose layouts possible.

Digital tools like Building Information Modeling (BIM) have further revolutionized design precision. AI-based simulations predict how structures behave under stress, while modular construction allows components to be prefabricated off-site for faster, safer installation. These technologies make building at scale not only achievable but also economically viable.

| Megastructure Type | Primary Function | Structural System |

|---|---|---|

| Skyscraper | Mixed-use development | Core + Outrigger + Steel Frame |

| Bridge | Transport infrastructure | Suspension or Cable-Stayed |

| Airport Terminal | Passenger circulation | Space Truss Roof + Modular Support |

Engineering Marvels — Structural Innovations Shaping the Region

Long-Span Bridges and Airport Terminals

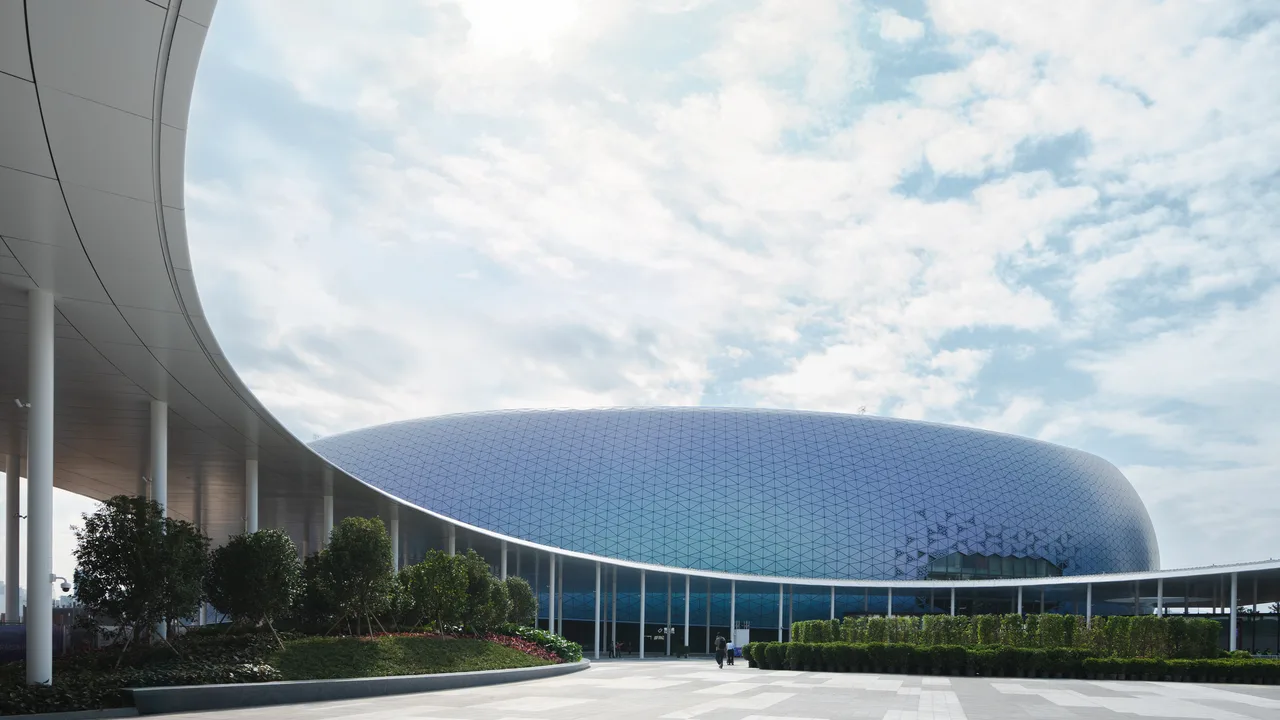

Beyond towers, Asia’s mastery of engineering marvels extends to infrastructure that connects nations. The Hong Kong–Zhuhai–Macau Bridge, stretching 55 kilometers, is the world’s longest sea crossing — a combination of bridge, tunnel, and artificial island built entirely with high-grade steel. In China, the Beijing Daxing International Airport employs a radial steel space-frame roof that spans over 700,000 square meters, designed for both efficiency and elegance.

These projects reflect a trend toward hybrid engineering — combining architectural vision with digital fabrication. They also highlight Asia’s unique approach to public infrastructure: treating functionality as an opportunity for artistry.

The Integration of Sustainability

Megastructures today are not just about scale; they are about stewardship. The integration of renewable systems, low-emission materials, and passive design strategies is turning Asia’s skyline into a showcase of responsible growth. From solar-integrated façades to high-efficiency HVAC systems, sustainability is now engineered into the DNA of modern structures.

Recycled steel, smart monitoring systems, and AI-based energy management platforms are further improving operational efficiency. Architects and engineers alike are embracing these methods to align innovation with environmental consciousness — ensuring that progress doesn’t come at the planet’s expense.

Behind the Scenes — Inside the Fabrication Process

The Precision of Steel Manufacturing

Every steel megastructure begins not on-site, but in a workshop where precision engineering meets industrial craftsmanship. The fabrication process involves a series of stages — from digital modeling to CNC cutting, robotic welding, and quality inspection. Each beam and column is produced under strict tolerance levels to guarantee perfect alignment during assembly.

This level of control ensures that construction schedules remain predictable, even for complex geometries. It’s a process where the boundaries between manufacturing and architecture blur, and where craftsmanship is defined by data accuracy.

Case Example: A Leading Steel Structure Workshop in China

Many of Asia’s most ambitious megaprojects source components from specialized fabrication hubs. One such steel structure workshop in China has earned international recognition for its ability to produce custom steel assemblies for towers, stadiums, and logistics centers. Equipped with robotic welding lines, digital inspection systems, and large-scale truss fabrication facilities, it exemplifies how China has become a global leader in steel manufacturing.

By integrating advanced production technology with international standards, these workshops are redefining what’s possible in megastructure construction — achieving not only precision but also sustainability and cost control on a global scale.

Structural Resilience and Safety

Designing for Seismic and Wind Forces

Asia’s geography presents some of the world’s most challenging conditions for tall structures. From typhoon-prone coastlines to earthquake zones across Japan, Indonesia, and western China, every steel megastructure must be engineered for resilience. Structural engineers use advanced simulations to anticipate wind pressure, vibration, and lateral displacement long before construction begins.

Modern towers employ tuned mass dampers—giant pendulum-like devices that counteract motion during high winds or tremors. Composite steel-concrete systems combine the flexibility of steel with the rigidity of reinforced concrete to achieve higher levels of safety. These innovations ensure not only structural integrity but also occupant comfort, as even minor building sway can cause concern in tall environments.

Lessons from Past Megaprojects

Many of Asia’s greatest engineering marvels owe their success to lessons learned from earlier projects. The Taipei 101 Tower, for example, pioneered wind-resistant design using a massive internal damper weighing 660 tons. Its success influenced a generation of skyscrapers throughout the region. Meanwhile, Japan’s post-earthquake reconstruction initiatives have set the global standard for seismic preparedness, pushing continuous research in foundation isolation systems and flexible joint technology.

Such iterative innovation defines Asia’s approach to progress — each structure serving as a prototype for the next. By combining rigorous testing, local expertise, and digital tools, engineers continually redefine the limits of what steel can achieve.

The Future of Steel Megastructures in Asia

Smart Cities and Adaptive Buildings

The next frontier of the steel megastructure movement lies in integration — linking architecture, data, and sustainability. Smart cities are emerging across Asia where buildings communicate with infrastructure through sensors and real-time analytics. Embedded IoT devices monitor temperature, air quality, and structural stress, enabling proactive maintenance and reducing lifecycle costs.

Adaptive building systems will also transform how cities function. Future towers will adjust ventilation based on occupancy, shift façade shading to control heat gain, and store excess solar energy for later use. These self-optimizing systems redefine what it means to be energy-efficient, blending human comfort with digital intelligence.

Regional Collaboration and Export Expertise

Asia’s influence extends far beyond its borders. Many regional firms now export not just materials but also expertise — from project management to modular fabrication. Cross-border collaboration is driving faster development cycles, with international teams designing, manufacturing, and erecting structures in record time.

China, in particular, has emerged as the engine of this transformation. Its large-scale workshops, standardized steel grades, and efficient logistics networks enable complex projects to be executed with precision. From industrial plants in Southeast Asia to stadiums in Africa, Asian engineering is setting new global benchmarks for speed and scalability.

Beyond Engineering — The Cultural Impact of Megastructures

Architecture as a Reflection of Identity

Each steel megastructure rising across Asia tells a story far beyond construction. It represents ambition, resilience, and the desire to define a national or cultural identity through design. Towers and bridges have become new monuments — symbols of confidence in an interconnected world. Just as cathedrals once defined Europe’s cities, megastructures now represent Asia’s future-forward spirit.

This blending of culture and engineering is particularly visible in projects that merge traditional motifs with modern form. The lattice-inspired façades of Middle Eastern skyscrapers and the pagoda-like silhouettes of East Asian towers remind us that technology and tradition can coexist gracefully in architecture.

Education and Skill Development

The region’s focus on innovation has also inspired a new generation of engineers and architects. Universities and technical institutes are emphasizing interdisciplinary learning — merging architecture with computer science, robotics, and materials research. These programs ensure that Asia remains not only the largest construction market but also the leading hub for design education and experimentation.

Conclusion — Redefining the Skyline

The story of Asia’s steel megastructure boom is a story of reinvention. It’s about how nations once known for fast-paced urbanization have evolved into laboratories of engineering precision and sustainable design. With each completed project, Asia demonstrates that the future of construction lies not in imitation but innovation — in merging art, science, and technology to create structures that stand as both functional assets and cultural landmarks.

As new materials, digital tools, and green technologies continue to advance, Asia’s megastructures will only grow smarter, lighter, and more efficient. The region’s skyline, already dazzling, will become a living showcase of what human imagination can achieve when supported by engineering excellence. In the steel bones of its towers and bridges, the blueprint of the future is already being built.